Why this name? Well, when Suzuki

went from the flat square-4 (RG500B) , to the stepped square 4

(RG500 “C”, or “Gamma” ) it was

generational change, from Beta, to Gamma. What we

were proposing to do was also a major change to the powerplant:

an upgrade to modern Grand Prix technology. The Gamma

engine was a significant evolution of the RG500B, so, I chose

Delta to designate the next stage..so now it’s an

RG500 Delta!

The Delta project would ultimately

involve modified crankshafts,different rods, all-new

cylinders, and custom-built heads, not to mention a new,

completely adjustable digital ignition. To round off the

project, I incorporated massive bracing to the frame to try and

shore up a classic weak point on my RG500.

I am not the smartest guy in the

world. For some reason, after developing my RG500’s

motor to the point where it made 127 hp and 66 ft-lbs of usable

torque, I junked it and started over by swapping TZ250 barrels

onto my RG500s cases. I thought a home-brewed, disc-valve

RG/TZ500 would be pretty cool. Well, the search for

killer power has been a cruel -and expensive- mistress.

Nontheless, it has been a very interesting experience and

I got to work with some great people. Ever wonder what

goes into building some crazy special? This is our story...The

Tale of the RG500 Delta!

Before Project Delta even began, my RG500

had made over 45 dyno pulls. It now (Sep 2002) has over

100 dyno pulls on it. I spent a fair bit of effort in

the last few years learning how it responded to different

compression, porting, pipes, intake systems, ignition curves,

you name it. When the smoke cleared (literally) we had an

amazingly flexible disc valve motor than pumped out great power

from 7500 rpm, and over 60 ft-lbs from 8500 to 10000 rpm,

peaking at 66 ft-lbs on the Dynojet. With the addition of

an exhaust water injection system, the powerband started 1000

rpm lower. A fully programmable ignition would have

fattened the power spread even more. It would have been

easy to get higher peak power, but I do track days and the

occasional race with this bike and longevity was the order of

the day, so we kept the revs reasonable. The motor made

good BMEP, pushing 160 psi using net hp, so we did OK with a

motor that was designed in 1985!

Then I got greedy.

An innocent discussion on the RG500

mailing list (RG500@xs4all.nl) brought up the topic of what it

would take to get really insane power from one of these things.

127 hp pushing a 350 lb (fully wet) bike isn’t bad,

but I slavered at the prospect of 150-160+ hp and bottom end,

to boot. A few guys have swapped on barrels from the

RGV250 streetbikes, but it was a pretty big job, and for modest

power gains. I had seen reports of 135 hp - no dyno

sheets though- but we could do that with the current motor if

we wanted. Hardly worth the effort when we were already at 127.

A lot of guys had done 550cc kits but we creamed them for

midrange and peak with the well-sorted 500cc motor.

(This was before Mark Dent showed up!) Again, not worth

the effort.

We tossed around the idea of making

modern barrels from scratch, and one list member even had

access to the facilities to do it. However, this was a

bit too daunting- no takers. Then a friend suggested

skipping all the streetbike BS and installing TZ250 top ends.

Same bore and stroke, 56 x 50.6. hmmm! A parts

supply as close as the Yamaha dealer, stretching into the

forseeable future. Upgradable to latest-model TZ cylinders

whenever money allowed it. Race-bred breathing that had

the potential to develop 160-180 hp in 4 cylinder trim.

Irresistable! I knew this would be a heavy job and

enlisted the aid of my unofficial tuner, Darcy Rosentreter, of

Darcy’s Race Pipes in Winnipeg. As far as I am

concerned this guy is next to God for making a 2 stroke go.

No BS, just incredible results. And nice, to boot.

I suppose most 2 strokers feel the same way when they

hook up with a really good tuner. He built a normally

aspirated, 230 hp Vmax snowmobile and kicked the hineys of

pretty much all the big-name opposition at the World Series. .

Will that do?

Rocky Stargel, a friend who raced a late

modelTZ250, had spare barrels he measured out for us, and Darcy

figured that it just might be a doable swap with a bit of

machining on the barrels and a set of adaptor plates.

From this point on, I have to give 90% of the credit to

Darcy, as he designed the adaptors, set up all the clearances,

and facilitated the necessary crank work. So when I

say “we did this” and “we did that”, it

was me chasing Darcy around yapping like an excited pup while

he figured out how things would fit together.

Rocky also happened to have 4 spare

complete top ends he was willing to sell cheap, to help out

with the project. I couldn’t resist- I sold my ZX6R

supersport bike and bought the TZ250 parts.

Rocky shipped me the stuff asap and in a

week I was like a kid at christmas, opening boxes of

menacing-looking TZ cylinders, heads, and powervalves.

Darcy had already seen TZ stuff and was forming his

battle plan, but for me out came the ruler and I got my first

impression of what he had been talking about.

Just to lay a bit of groundwork,

the RG500 Gamma is a stepped, square 4 engine. A pair of

twins, on a common case, geared to a single intermediate shaft

in the center. 56 x 50.6mm layout with individual

cylinders and paired cylinder heads. Front cylinders

exhaust out the front, rear cylinders go straight out the back.

The TZ250 we wanted to use is a V twin, with individual

heads but the same bore and stroke.

The whole project was this sort of

exercise.

The swap broke down into major and minor

areas of consideration.

Major:

Adaptor plates: thickness? to be

determined by the final desired piston protrusion, but we had

to

settle on a connecting rod first.

what to do about coolant routing

from the case into the barrels

max external dimensions

material

placing all the stud holes, thread

holes, transfer ducts, coolant passages, and sealing surfaces

so they didnt get in each other’s way.

do we handmake the pieces, or get

them digitized and CNC cut so my pack of drooling friends could

follow in my footsteps? cast them or machine from solid

stock?

Crank mods: we needed to buy enough room

for an adaptor plate to fit under the TZ barrels. The RG

uses a 100mm rod, the TZ, 110mm. It seemed logical and

convenient to look for a suitable 110mm rod to more closely

emulate the TZs setup, as this would also gain us precious room

under the barrels. The yet-to-be-found rod would need to

fit my RGs crankpin and the yet-to-be-found piston’s pin.

The yet-to-be-found pieces were beginning to stack up. Of

course, after all these new parts were hung on the crank, it

would need to be rebalanced- but to what balance factor?

Pistons: Must have a full skirt

(aha! a starting point) and fit the TZs 56mm bore. Offset

pins a plus if reversible. Single ring preferred. Must be

able to withstand 350 Bhp/liter, so no 1962 Bultaco stuff.

Can use a larger pin than the con rod, if it comes down

to it, as we could use crowded rollers on the small end if need

be. An example would be using a piston

designed for a 16mm wristpin on a rod intended for a 14mm

pin. Just use the 14mm pin and pack in 2mm roller

bearings with no cage, just install as many as will fit in and

pack it with grease so they stay put till you get the pin in

place. Apparently this is yet another racing trick as the

cage, at ultrahigh rpms, has enough inertia to slam against the

rollers and make them skid when its time to reverse direction.

Get rid of the cage, and all the roller element have to

do is reverse their own rotation, with no cage bashing into

them every revolution. That’s the story, at any

rate. Don’t call me on any of this stuff because I

had never heard of half of this before!

My scooter, unclothed

Readout from my

RG-barreled motor

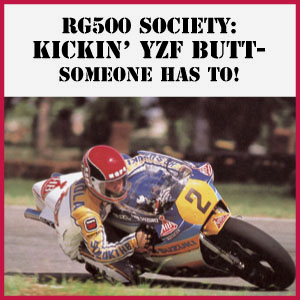

Just a little nag for my

R1 buddies!