The Wolf ignition system is still in use on this engine. It

controls a 3D advance curve by taking RPM and throttle position

inputs. It automatically swaps to a milder advance curve

in 6th gear (reads a gear selection sensor) to stave off

detonation. It controls the water injection system on/off

points and checks switching RPM to throttle position. it has

built-in control for quickshifter operation.

Unfortunately, the TZ requires a very large amount of ignition

advance, more than I can get from the Wolf igntion when the

stock timing mark (on the crank) is used. This winter

we’ll relocate the timing notch to about 45 degrees BTDC

so I can get a full advance curve on the engine. So far I

have been as much as 10 or more degrees behind what a stock TZ

needs for advance. Hopefully this will help to wake the

engine up, next spring. We plan to swap crank wheels from

side-to-side, and cut a new notch in one of the currently

virginal crank wheels.

Thus far, I’ve been using

modified “Darcy pipes” , which were designed around

the OEM RG barrels and at 113mm are much too skinny for TZ

application. They were also too long, and I had to

shorten them considerably. Actually, they’ve been

chopped and modded about 3 times, now. We have a new

pipe spec sorted, which is very similar to a std TZ pipe,

which should also help to wake up the engine next spring.

The plan is to allow the pipes to run up to 11500 or

11750 rpm, and use water injection to fill in the lower part of

the powerband.

Water injection is a big part of

this package. Still controlled by the CDI, it should be

able to reduce peak torque rpms to 9000/ 9500 RPM when

activated. Hopefully we’ll be able to get a very

wide, and high, plateau of torque in the 70 ft-lb range, while

still revving out to 11700 or so. In theory, that ought

to be good for 155 hp.

Frankly, I had no idea what to

expect when I got this thing running. Initially, I had to

deal with crazy low-end carburetion. But, that

didn’t prevent me from riding it. What I found was,

the motor made better power in the 5000-6000 rpm range than my

old RG setup. I attribute this to the excellent

powervalve, which drastically reduces the height of the exhaust

valve to something more suited to a trials bike. It ran

well on top but oddly enough, still peaked at 10300 or so, like

my old motor. None of the screaming, 12,000 rpm power I

had been expecting. Now, I knew my pipes were designed to

peak at 10.2 or so, but I figured that with all this extra

exhaust port height, it would still rev out higher than the old

barrels. No dice. A trip to the dyno revealed

125 HP and 65 ft-lbs, but much less upper-midrange than

my old setup. Damn! Were the pipes so long that

they were beyond some critical threshold, where the ports just

didn’t work like they were supposed to? I cut the

pipes down a few inches. Bingo- 12,000 rpm power-

but was it any faster? Another trip to the dyno.

Still at 125 HP, but now it had to do 11000 rpm to do it.

This time, though, I had overrev to end all overrev.

It would easily do 12k, and even with the powervalves set

in the low rpm position, it revved to the moon. Anyhow,

it was no real improvement.

Next, I cut the pipes a bit more, in the

headpipe, to try and bring the vacuum vace back into synch with

the stuffing pulse. result? 125 hp, but now at

11500 rpm. Shit! Powerband was considerably

narrower than what I had when using the RG barrels.

I rode it like this for the rest of that

year. The next spring, I planned to go to Daytona and

contest the Brute HP shootout at AMI. I had a few mouths

to shut, and I did call out Mr Lance to bring his best bike

down to Daytona and run against me on the dyno in front of

everybody, as he had been investing quite a lot of time and

energy telling people that I had been falsifying my dyno

numbers.

Preparation- Pete bored the carbs

to 36.5mm and I enlarged inlet passages, and advanced timing

another 4 degrees by altering the location of the timing pickup

in the case. Still a good 10 degrees from where it needed

to be. but, it was all I could do. UNFORTUNATELY

(and this is a big one) the shrouds surrounding the main

air bleed entries had been machined off as part of the carb

boring process. I didn’t realize that those babies

HAD to be on there for it to run right. And so...

I ran off to my local dyno guy to test

ignition curves, disc valves, and my next generation pipes.

I also took a can of VP-MR2 oxygenated fuel. I had

to leave for daytona in a few days! What happened was,

the bike would pull on the dyno up to 11,000, then suddenly go

so lean that it would begin barking and backfiring out the

carbs. No matter what I did with jetting, it just would

only run to 11,000 rpm. All the rest of my testing was

rendered moot by this development. I returned home to

try and sort it, and came back day or 2 later.

Shit!! Still ran to 11k and

stopped. It pulled 132 Hp (134 on one jagged run,

but that stuff doesn’t really count) at 11000 with the

power curve climbing sharply, but at 11k it was all over.

After exhaustive tests, I dragged out of there, with

nothing to show for it but new problems. We even tried

the MR2 on the low CR heads, and it hurt power. Damn!

I talked to a few guys, including some

vary sharp tuners, and got suggestions that covered everything

from alien electronics to fuel frothing. I went to

Daytona with car wheel tape weights to stick to my float

bowls..

A few days of struggle in Daytona

revealed no solutions.

The bike just would not run above 11k.

I was even trying to alter the main air bleeds by

epoxying them shut and retapping to a smaller size. I

tried to find air jets: I searched all of Daytona, IN BIKE

WEEK, FOR GOD’S SAKE, and could not find air jets.

I tracked down the Mikuni guy at his giant trailer

outside of Harley Davidson of Daytona. O Mikuni Guy, I

said. I need and assortment of main air jets! And I

listed the sizes. “Nobody’s ever asked me

that before”, he said. And sure enough, he had no

fricking air jets.

I called Darcy in a panic. By this

time, I was considering whether the loss of the main air

bleed shrouds was causing a problem. I had managed to

contact My Favorite Journalist (Kevin Cameron) and he pointed

out that many bikes use controlled airflow across the air bleed

entries to create certain effects at high intake airflows.

Removing the shrouds would certainly have an effect.

Thanks, Kevin! Darcy recommended epoxying aluminum

tubes back into place to shround the entry to the air bleeds.

Voila! it ran perfectly. Too bad I had

completely wasted two trips to the dyno back home. I

slapped it all together and ran off to AMI to run it. My

water injection system was dead because of rust in the steel

lines, so I was running without. The guy asked me where

to gas it, so I said 6500 or something like that. He got

it to 6500 and gassed it.. and it fell right on its face.

Remember that rich hole? Instead of getting off

the throttle, like we would do, he held it open hoping it would

clear out.. but instead, it fouled a plug or 2. I think

it registered 50 hp or something like that. I had to limp

home on 3 cylinders.

I thought boost bottles might help.

I had calculated the volumes and hose lengths for boost

bottles to help with the rich spot, and had already made the

bottles, so I installed them. They actually worked pretty

well, till the gasoline fumes melted the plastic I had

used. Damn!

I decided to fix the crippled water

injection. I spent tuesday night installing new stainless

lines, a new pump, and cleaning out all the fittings and

injectors. I installed the 16:1 heads and filled it with

MR2 fuel. One test ride- it worked like a charm.

No flat spot with that little blue water injector light

winking. And it was faster than holy F%^&. Wed

I was back to AMI bright and early. The top 600 had

posted 103 HP, I believe. We ran my bike up on the dyno

and it ripped, spinning the back wheel on the drum but posting

something like 118 HP. You only get 2 pulls, so that was that.

With the shootout lead, I ran off home. I

rode around all day and decided that the high CR setup was

really no better than my low CR setup. I burned up the

rest of the stinky fuel, which was now enough to make me

sick with one whiff, flushed it out and changed back to Amoco

92. The 102 is too slow-burning for my low CR setup, I

had seen that before when running high octane Swapped on

my 14:1 heads. Went back Thursday and insisted that they

strap the bike down really tightly. It banged out 128.6

Hp on the Superflow, still climbing sharply at 11750 when the

rev limiter kicked in. The correction factor for that day

placed it at 138 dynojet HP- I was pretty happy with the

result, and also with the correlation of my dyno back home,

with the superflow in Daytona. Whatever the absolute

numbers, I beat all the GSXR750s there and was 4 Hp behind the

top R1, which had posted 132 HP. Vindication! ! whew.

An exhausting week. I think I worked as hard as any racer

at the track. Friday I came back to AMI and took the win

with a bye in the 600cc class, at 128.6 HP, as the 103 Hp ZX6R

was not likely to challenge. See the results HERE

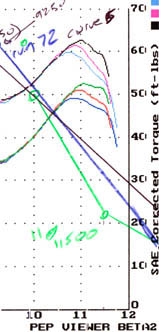

Early test of water injection. What

would you pay for a set of pipes that could extend your

powerband like this?

Dialling in the advance curve. Free

HP anyone? Various retard curves Vs Hp output. This

was when I had mysterious 11000 RPM leanout.

Another few runs showing the breakup at

11000 rpm. It was due to machined-off air bleed shrouds.

Look at how fast HP is climbing at 11K. When the

shrouds were fixed, it made 138 Dynojet at 11750 (rev limiter)

and was still climbing sharply. Who knows what it would

have made at 12 or beyond? It revs like a TZ250, after

all.